News

Super Factory Case: YSTEK Assists in Building an E - cigarette Packaging System with a Daily Output of 40,000 Bottles of E - liquid in US

In recent years, the e - cigarette market has expanded rapidly. As an important emerging market, US's demand for e - cigarette products has been on the rise. To meet the needs of large - scale production, YSTEK Machinery has successfully built a highly efficient e - cigarette packaging production line with a daily output of 40,000 bottles of e - liquid for a large e - cigarette manufacturer in US using its advanced YS series equipment. This project not only demonstrates YSTEK Machinery's leading technology in the field of packaging automation but also sets a new production benchmark for the e - cigarette industry.

YS Series Equipment: Empowered by Technology, High - efficiency Output

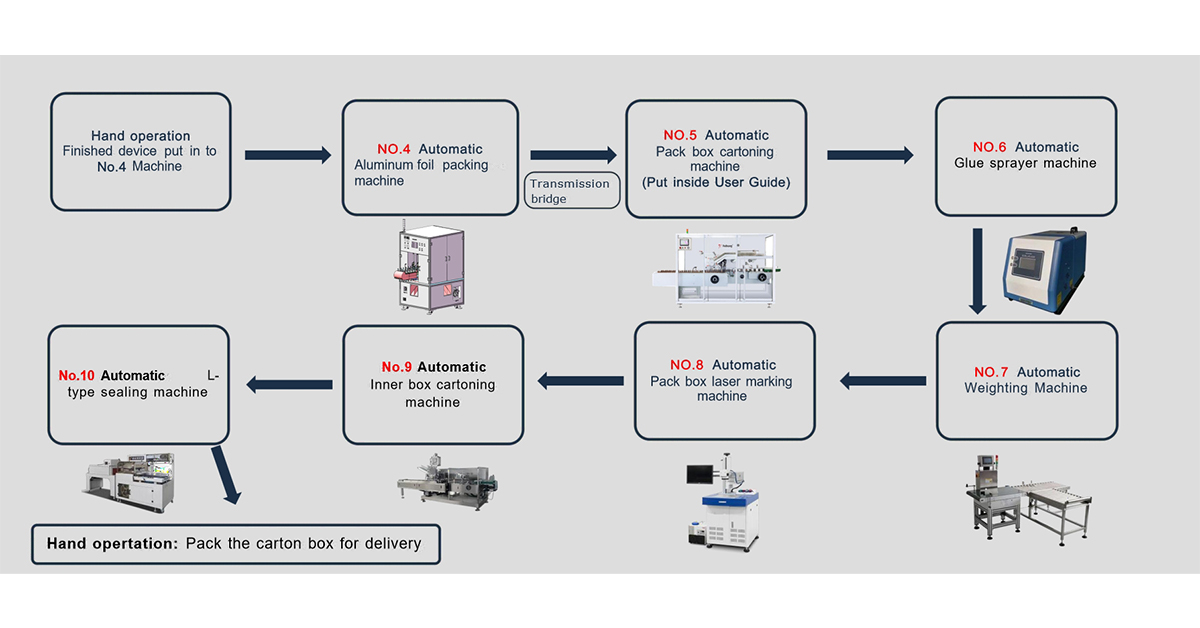

In this project, YSTEK Machinery selected a variety of YS series products, including core equipment such as the YS - 250 cartoning machine, the automatic e - liquid filling production line, and the L - type sealing machine, to build a complete e - cigarette packaging production line. Here are the application highlights of several key equipment in this project:

1. YS - 250 Cartoning Machine: High - speed and Stable, Precise Packaging

The YS - 250 cartoning machine is a high - tech equipment integrating machinery, optics, electricity, and pneumatics developed by YSTEK Machinery, specifically designed for high - efficiency production. In this project, the YS - 250 cartoning machine demonstrated its excellent performance:

High Speed and Stability: The equipment runs stably and can complete multiple processes such as instruction manual folding, carton opening, product loading, batch number printing, and carton sealing, greatly improving the efficiency of the production line.

Intelligent Control: The PLC control system, combined with photoelectric monitoring, can automatically stop the machine and display the cause in case of abnormalities, facilitating the timely troubleshooting. This ensures that the entire production line can operate without faults for a long time and guarantees a high daily output of 40,000 bottles of e - liquid.

2. Automatic E - liquid Filling Production Line: Precise Filling, Quality Assurance

As one of the core equipment in this project, the accuracy and efficiency of the automatic e - liquid filling production line directly determine the production capacity and product quality of the entire production line. This equipment of YSTEK Machinery has the following characteristics:

High - precision Filling: The filling accuracy is controlled within ±1%, ensuring that the capacity of each bottle of e - liquid is accurate and eliminating product defects caused by insufficient or excessive filling.

Intelligent Rejection System: The equipment has an upgraded detection function for the dropping of the inner bottle stopper. Unqualified products will be automatically rejected to avoid flowing into the next packaging process, thus ensuring a high qualified rate of finished products.

Flexible Configuration: According to customer requirements, this production line can be configured with 2 - head or 4 - head filling pumps, and ceramic pumps and peristaltic pumps are provided as options, greatly improving the adaptability of the equipment.

3. L - type Sealing Machine: Fast Sealing, Tight Protection

In the sealing process, the L - type sealing machine undertakes the task of fast and efficient heat sealing:

Integrated Sealing: When the packing box passes by, the L - type sealing machine automatically completes the sealing work of the packing box. The seal is tight and beautiful, meeting international quality standards.

High Speed: It can complete the sealing of 55 - 65 packing boxes per minute, fully ensuring the smooth operation of the entire production line and meeting the production capacity requirements.

Overall Efficiency of the Production Line: Seamless Docking, High - efficiency Operation

The highlight of this project lies in the seamless docking and linked operation of the entire production line. Modules such as conveyor belts, transfer bridges, and automatic robotic arms cooperate with each other to achieve integrated operations from e - liquid filling, cartoning, sealing to case packing. The coordinated operation of the equipment not only improves production efficiency but also greatly reduces the errors of manual operations. The high degree of automation of the entire production line enables the factory to manage the entire production process with only a few technicians, fully demonstrating the advantages of unmanned production.

Project Results: Helping Customers Reach New Heights

After the successful implementation of this project, the customer's factory can stably produce 40,000 bottles of e - liquid per day. The production efficiency and product quality have been greatly improved, successfully meeting the growing local market demand. In addition, the customer highly recognizes the comprehensive technical support and services provided by YSTEK Machinery.

RELATED NEWS

- Comprehensive Packaging Line for E-Cigarette Assembly and Testing 2025-07-16

- Streamline Your Production with Automated Cartridge Box Packing Machines 2025-07-18

- Efficient Liquid Filling and Capping Solutions for Vaping Products 2025-07-19

- Sustainable Vape Liquid Filling & Packaging Solutions 2025-07-27

- All-in-One Vape Device Packaging Automation 2025-07-20

Categories

Latest News

Contact Us

Contact: FONG

Phone: 86-15013113213

E-mail: info@ystekpac.com

Whatsapp:86-15013113213

Add: No. 30 Xinhong Road, Lincun, Tangxia Town, Dongguan City, Guangdong Province