News

Full E-cigarette Packaging Line: Eliquid Filling - Assembly - Packaging Technology

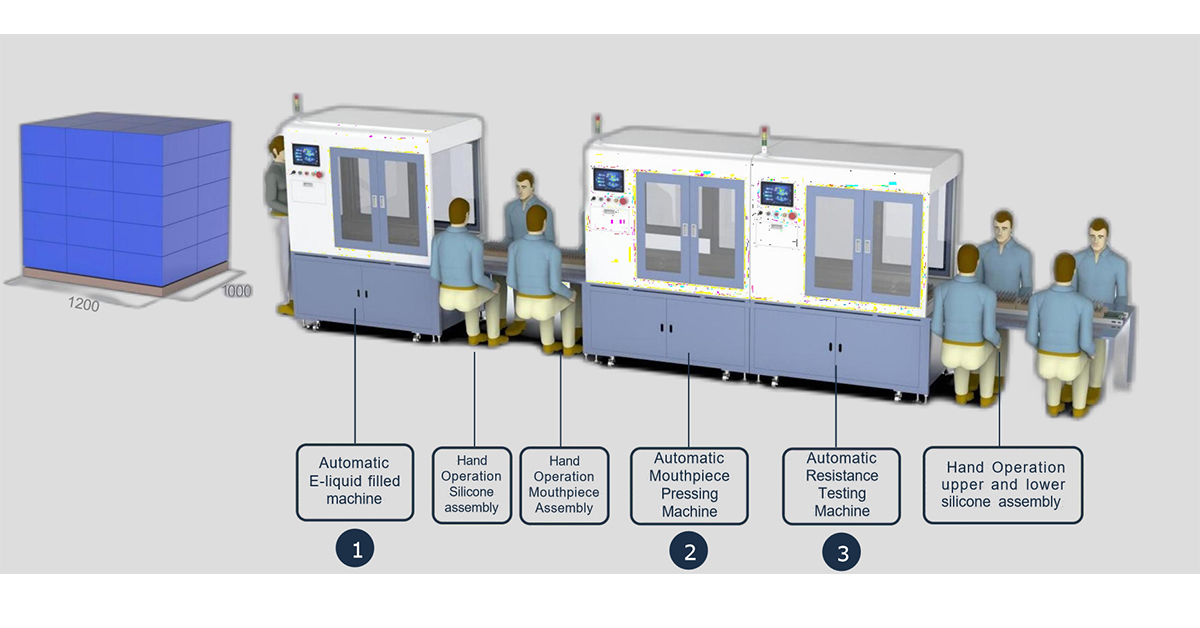

Part 1: Semi - automated Oil Filling and Assembly Equipment

1. Equipment Specifications and Layout

Layout Method: Semi - automated multi - machine docking assembly

Production Capacity: 2,400 pieces per hour

Defective Product Handling: Automatic filtering and rejection

Equipment Dimensions: 7.5m (length) × 1.0m (width) × 2.0m (height)

2. Workstation Functions

Automatic E - liquid Filling Machine: Precisely inject e - liquid.

Manual Silicone Assembly Station: Manually assemble silicone components.

Automatic Mouthpiece Pressing Machine: Press the mouthpiece components.

Automatic Resistance Tester: Detect the resistance value of e - cigarettes.

Manual Mouthpiece Assembly Station: Manually assist in the installation of the mouthpiece.

Manual Silicone Assembly Station: Manually assemble silicone components.

3. Operation Process

Place the fixture tray on the conveyor belt → E - liquid filling → Assembly of silicone and mouthpiece → Resistance testing → Rejection of defective products → Transfer of qualified products to the automatic packaging machine.

4. Equipment Characteristics

Status Indicator Light: Three - color display (running/fault/standby).

Human - Machine Interface: Touch screen + operation keyboard.

Dust - proof Design: Equipped with a dust cover and operating system.

Double - door Design: Front and rear double doors for easy maintenance.

Fixture Capacity: 50 pieces per tray.

5. Key Modules

Transfer Module: Linear transmission system.

Five - needle Automatic Liquid Filling Head: High - precision filling.

Four - station Resistance Tester: Efficient multi - channel detection.

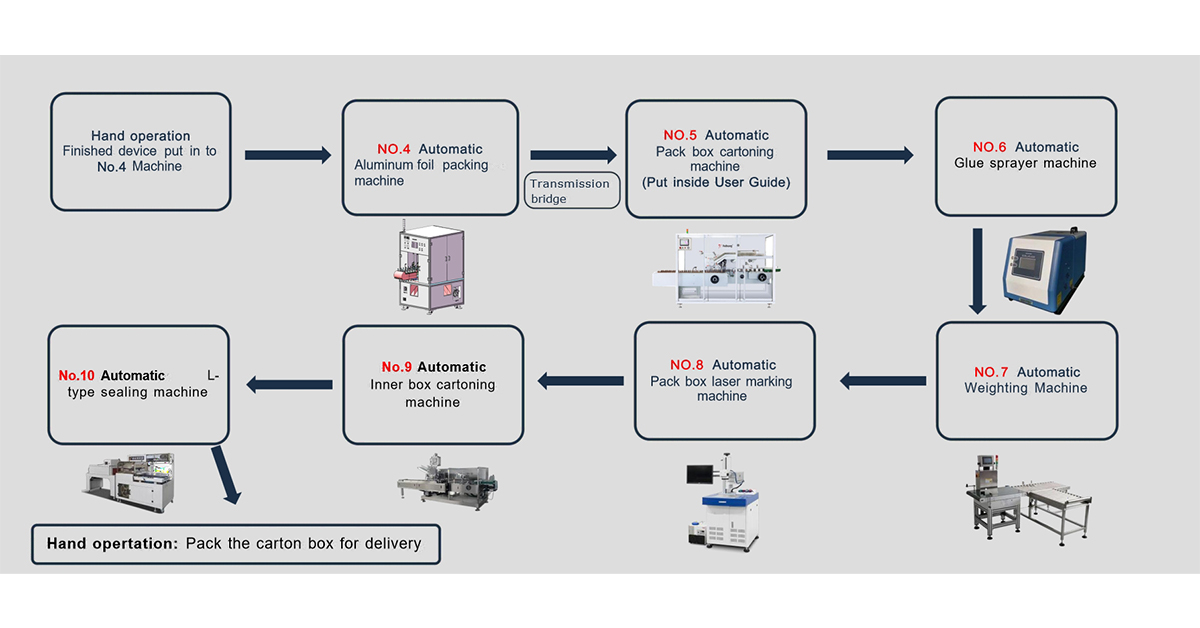

Part 2: Automated Packaging Equipment

1. Equipment Composition and Functions

Aluminum Foil Packing Machine

Dimensions: 1.50m × 0.90m × 1.05m

Weight: 800kg

Speed: 55 - 65 pieces per minute

Box - in - Case Packing Machine

Dimensions: 3.22m × 1.20m × 1.77m

Weight: 1,500kg

Speed: 50 - 100 pieces per minute

Inner Box Cartoning Machine

Dimensions: 4.50m × 1.50m × 1.90m

Weight: 1,800kg

Speed: 40 - 60 boxes per minute

L - type Sealing Machine: Automatically seal the packing box.

Laser Marking Machine: Print markings on the packing box.

Weighing Machine: Detect the weight of the finished product.

Gluing Machine: Package bonding.

2. Operation Process

Finished products into the case → Inner box cartoning → Aluminum foil packing → Laser marking → Weighing → Gluing → L - type sealing → Palletizing (5×2 arrangement) → Manual boxing and shipping.

3. Transmission System

Transfer Bridge: Connect each workstation.

Conveyor Belt: Continuous material transfer.

Production Capacity and Quality Control

1. Production Capacity Calculation

Single - shift 8 - hour Production Capacity: 2,400 pieces per hour × 8 = 19,200 pieces per shift

Monthly Production Capacity (29 working days): 556,800 pieces

2. Quality Inspection Equipment

Environmental Testing: High - low temperature test machine, salt spray test machine.

Mechanical Testing: Drop test machine, vibration test machine, abrasion test machine.

Electrical Testing: Battery internal resistance tester, button life tester.

Material Testing: Silicone hardness tester.

The intelligent control system of the full e - cigarette packaging line can automatically detect and adjust the production status to ensure the efficient operation

RELATED NEWS

- Comprehensive Packaging Line for E-Cigarette Assembly and Testing 2025-07-16

- Streamline Your Production with Automated Cartridge Box Packing Machines 2025-07-18

- Efficient Liquid Filling and Capping Solutions for Vaping Products 2025-07-19

- Sustainable Vape Liquid Filling & Packaging Solutions 2025-07-27

- All-in-One Vape Device Packaging Automation 2025-07-20

Categories

Latest News

Contact Us

Contact: FONG

Phone: 86-15013113213

E-mail: info@ystekpac.com

Whatsapp:86-15013113213

Add: No. 30 Xinhong Road, Lincun, Tangxia Town, Dongguan City, Guangdong Province