News

Vape Oil Filling Capping Machine for USA Market – High Precision & Low Cost Solution

Why the USA Market Needs Special Consideration

The USA market has stringent requirements when it comes to manufacturing and packaging standards. Regulatory compliance, precision in filling, and product safety are non-negotiable. A vape oil filling capping machine tailored for the USA market addresses these specific needs with advanced technologies such as:

PLC Control Systems for precision and automation.

Stainless Steel Contact Parts ensuring GMP compliance.

High accuracy filling with a margin of error as low as ±1%.

Features to Look for in a Vape Oil Filling Capping Machine

When searching for the perfect vape oil filling capping machine, especially for the USA market, you’ll want to prioritize machines with the following features:

High Precision Filling:

The machine must offer precise filling to avoid waste and ensure each bottle contains the exact amount of vape oil. For businesses focusing on quality control, precision is key. Machines offering ±1% filling accuracy are highly recommended.Automated Capping:

Automating the capping process not only speeds up production but also ensures tight and secure caps, preventing leaks during transport.Easy Cleaning and Maintenance:

Since the vape oil industry demands hygiene, choose machines that allow easy disassembly for cleaning. This minimizes downtime and ensures smooth operation.Customization Options:

Businesses have varying production demands. A filling capping machine that can adapt to different bottle sizes and filling volumes is a must. Look for machines with easy changeover parts to handle diverse product lines.

Why Choose a Low-Cost, High-Efficiency Vape Oil Filling Capping Machine?

Cost management is always a critical factor, especially for small to medium enterprises (SMEs) entering the competitive USA market. A low-cost vape oil filling capping machine doesn't necessarily mean sacrificing quality. By selecting the right machine, you can achieve high efficiency without breaking the bank.

For instance, the YSTEK Vape Oil Filling Capping Machine offers:

Automatic Operation for reduced labor costs.

Low Maintenance Costs due to durable materials and a simplified mechanical design.

Modular Structure for easy scaling as your business grows.

This machine also excels in production capacity, handling up to 2,400 bottles per hour, depending on the model. For SMEs aiming to optimize their operational costs while meeting the high standards of the USA market, this machine is a top contender.

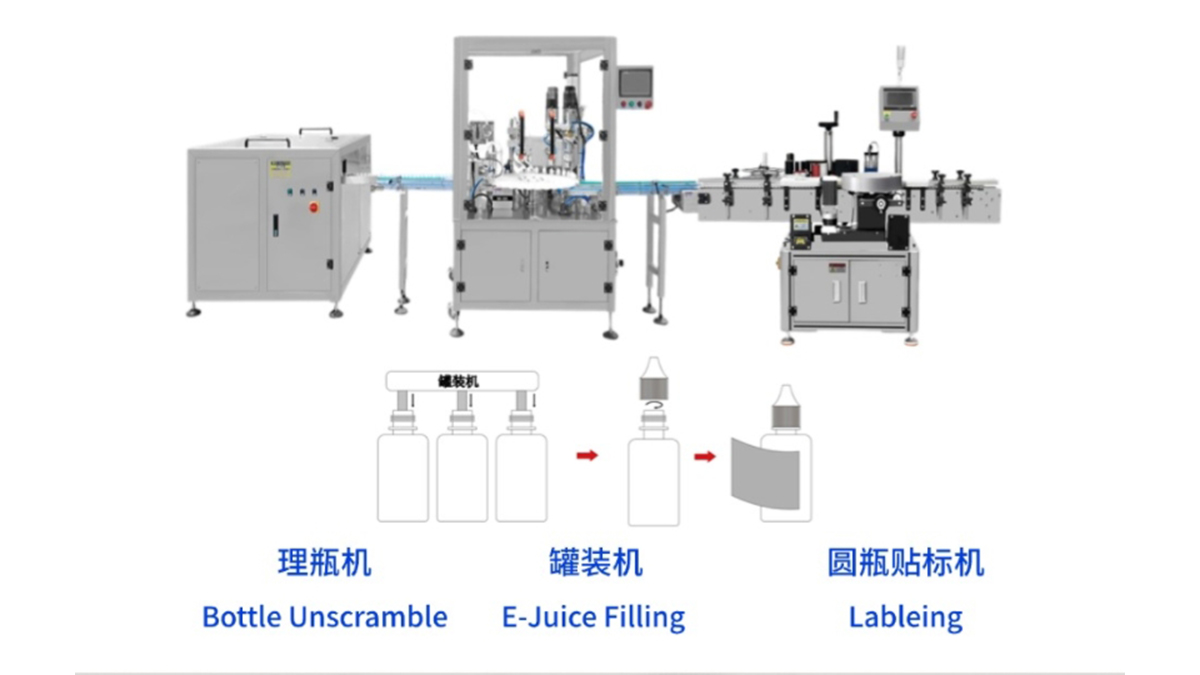

Integrating with Other Packaging Equipment

If you’re looking to streamline your entire packaging line, integrating the vape oil filling capping machine with other equipment such as labelers, shrink wrap machines, and cartoners can further enhance productivity. The YSTEK model, for example, can be paired with:

Automatic Labeling Machines for seamless packaging solutions.

Conveyor Systems to transition filled and capped bottles to other stations.

By building a complete line of packaging equipment, you reduce manual handling and cut down production time, further improving your operational efficiency.

Conclusion – Choose the Right Machine for USA Market Success

When selecting a vape oil filling capping machine for the USA market, it’s crucial to choose a solution that combines precision, cost-effectiveness, and adaptability. A machine that delivers high accuracy filling, automated processes, and easy maintenance can make all the difference in a competitive market landscape. Businesses that invest in equipment tailored to specific market demands—like the USA—are poised for long-term success.

Whether you’re new to the vape oil industry or looking to upgrade your current filling and capping processes, ensuring you have a machine that meets both regulatory and production standards is essential for growth in the American market.

Opt for low-cost, high-efficiency solutions, and propel your business forward.

RELATED NEWS

- Comprehensive Packaging Line for E-Cigarette Assembly and Testing 2025-07-16

- Streamline Your Production with Automated Cartridge Box Packing Machines 2025-07-18

- Efficient Liquid Filling and Capping Solutions for Vaping Products 2025-07-19

- Sustainable Vape Liquid Filling & Packaging Solutions 2025-07-27

- All-in-One Vape Device Packaging Automation 2025-07-20

Categories

Latest News

Contact Us

Contact: FONG

Phone: 86-15013113213

E-mail: info@ystekpac.com

Whatsapp:86-15013113213

Add: No. 30 Xinhong Road, Lincun, Tangxia Town, Dongguan City, Guangdong Province